POULTRY FEED MACHINERY PLANT MANUFACTURER

01

RAW MATERIALS

Poultry feed formulation involves a combination of various ingredients, including corn, sorghum, barley, rye, triticale, oats, soybean, canola, cottonseed, minerals, vitamins and oils such as turmeric and vegetable oils. The selection of specific ingredients is based on the specific nutritional requirements for different poultry applications.

02

INTAKE & CLEANING

Raw materials are fed into a hopper or batching bins in auto batching plants. Materials are weighed in a hopper based on the formula. Afterward, thorough cleaning occurs, removing impurities with magnets and jute twine/plastic strings are eliminated using a remover

03

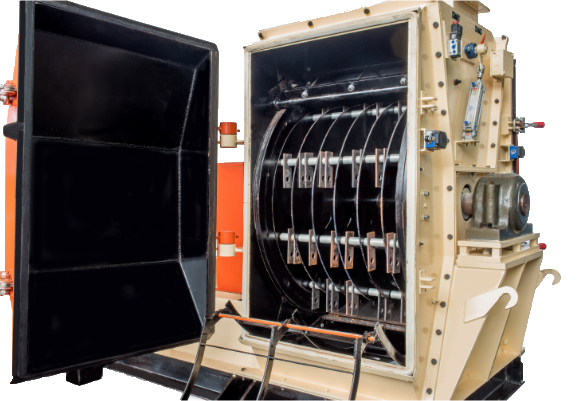

GRINDING

Cleaned batch is stored in a grinding hopper. Batch tracking prevents mixing, enabling entry into the hammer mill via a VFD-operated feeder. Grinder reduces raw material to 400-1000 micron particles. Despite grinding, batch isn't uniformly mixed yet, advancing to the mixing stage.

04

MIXING

A batch mixer, paddle or ribbon type, is in the mixing section. Guided by batch tracking, the entire batch enters and oil is added according to the formula. Oil, weighed in a dosing tank, is dosed in. Mixing lasts 3-5 mins: dry powder mixes 2 mins, then oil sprayed and wet mixing 3 mins. This achieves < 5% variation in sampling for homogeneous powder mixing.

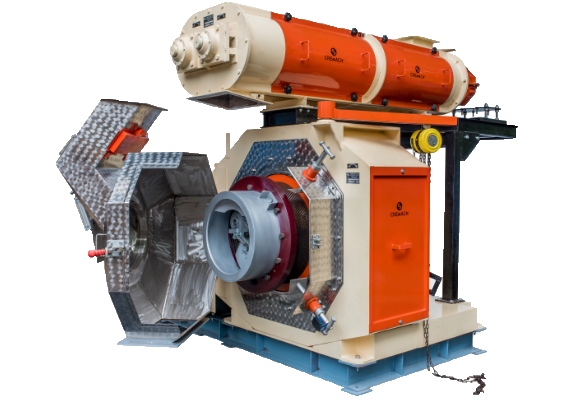

05

PELLETIZING & CRUMBLING

Wet steam conditions material, enhancing pellet quality and mill performance. Conditioned material is compressed and extruded through a die in the pellet mill, yielding 2.8 mm to 3 mm pellets. After cooling, pellets are crumbled into smaller pieces appropriate for chicks' age and weight, facilitating feeding.

06

SCREENING & PACKAGING

Crushed pellets enter a vibratory sieve for precise sizing. The end product is stored in a bagging bin, weighed and then packaged for distribution. Cremach specializes in advanced poultry feed machinery, ensuring top-notch nutrition and livestock performance. Our meticulous craftsmanship and superior equipment ensure dependable and uniform feed production for your animals.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.