CATTLE FEED MACHINERY PLANT MANUFACTURER

01

RAW MATERIALS

The ingredients used in cattle feed production include wheat bran, rice bran extraction, De-oiled cake, maize, damaged wheat, cottonseed, molasses, salt, calcium carbonate, mineral mixture and vitamin mix. The selection of specific ingredients depends on the desired application and nutritional requirements.

02

INTAKE & CLEANING

The raw materials are carefully fed into a dumping hopper or stored in individual batching bins for automatic batching plants. Prior to processing, the raw materials undergo thorough cleaning to remove impurities. This involves separating ferrous impurities using magnets and eliminating jute twine and plastic strings through a jute twine remover.

03

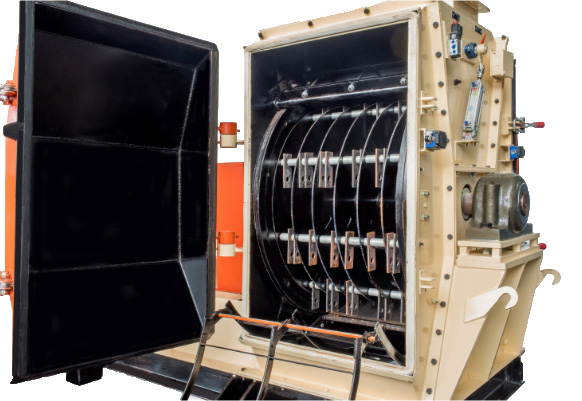

GRINDING

Once cleaned, the batch enters a grinding hopper and is fed into a hammer mill (grinder) via a variable frequency drive (VFD) operated feeder. The grinder reduces the raw material to a particle size of typically 600-1200 microns. Although the batch is ground, it is not yet uniformly mixed and thus proceeds to the mixing stage.

04

MIXING

The mixing section features a batch mixer, either a paddle or ribbon type. The entire batch, guided by the batch tracking system, enters the mixer, where it is thoroughly mixed. The typical mixing process takes approximately 3-5 minutes, ensuring a homogeneous blend with a < 5% variation in sampling.

05

MOLLASIFYING

After mixing, the material enters the molasses addition section. The molasses, sourced from a preheated storage tank, is introduced using a VFD-operated pump. In cases where pelletizing is not required, the material is directly transferred to the mesh bin for packaging.

06

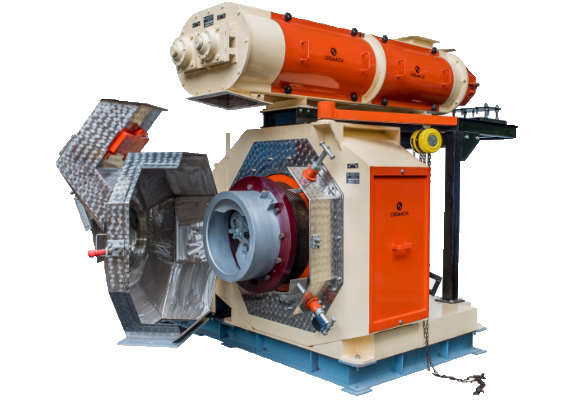

PELLETIZING

For pellet production, wet steam is supplied to condition the material and improve pellet quality and operational characteristics in the pellet mill. The conditioned material is compressed and extruded through a die, resulting in 4 mm to 10 mm diameter pellets.

07

SCREENING & PACKAGING

The pellets undergo cooling through a cooler and sizing through a vibratory sieve before being stored in a bagging bin for distribution. At Cremach, we specialize in cutting-edge cattle feed machinery to enhance livestock nutrition and performance. Our precision equipment ensures reliable feed production.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.

Copyright Cremach Pvt Ltd. 2023. All

Rights Reserved.